Loading...

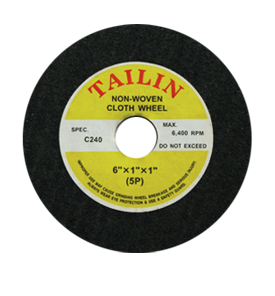

Our Products

Top Products

Contact Us

| PROBLEM | POSSIBLE CAUSE | SOLUTION |

|

Wheel Loading |

|

|

|

Wheel Glazing |

|

|

|

Wheel Breakage |

|

WARNING: Stop all operations. Take time to solve the problem. If it persist, call your local representative. |

|

Chordal |

|

|

|

Radial |

|

|

|

Slow Cut Rate |

|

|

|

Work piece Burn |

|

|

|

Non-Square Cuts |

|

|

|

Short Wheel Life |

|

|

Home | About Us | Products | Technical Info | Customer Care | Contact Us

All Rights Reserved 2012 | Tailin | Powered by: KWT Computer Systems, Inc.